Can the test time for product air tightness testing be adjusted?

Answer: Yes, it is fully adjustable.

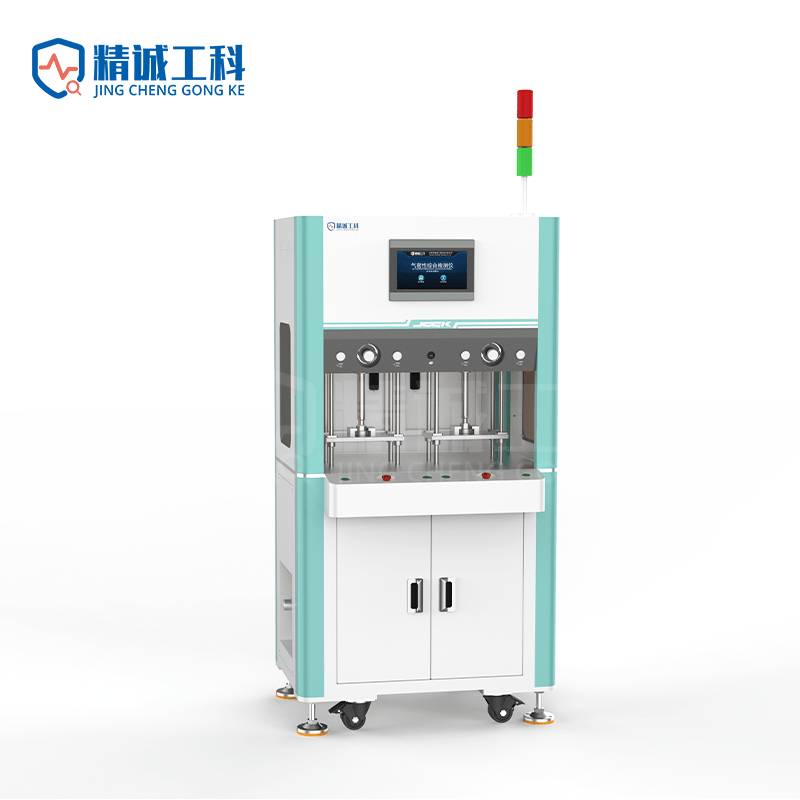

modernityAirtightness TesterThe test time is not only adjustable, but also very flexible.

I. Why do you need time to regulate?

Different standards have different requirements

- IP67 Standard: 1 meter underwater, 30 minutes

- IP68 Standard: More than 1.5 meters under water, continuous immersion

- IPX8 Standard: Manufacturer-defined rigors

Each standard corresponds to a different test duration, and a fixed time simply doesn't cut it.

Cell phone air tightness test case, 20 seconds to complete the product sealing waterproof test

Product Characteristics Determine Testing Strategy

The sealing structure, material properties, and size of different products all affect the optimal test time. A cell phone may take as little as 20 seconds, while a large product enclosure may take several minutes.

Second, how do you specifically regulate it?

Traditional water immersion

The test time is usually between5 minutes to 2 hoursAdjustable between, the length of immersion is controlled by a timer.

Modern airtightness testing methods

in order toPrecision EngineeringAir tightness test equipmentAs an example, the testing process is divided into four stages, each of which can be adjusted independently:

| testing phase | time scale | Typical setup | regulatory significance |

| inflation stage | 1~10 seconds | 3~5 seconds | Ensure stable chamber pressure |

| equilibrium | 2~30 seconds | 5~10 seconds | Allow the pressure to stabilize sufficiently |

| detection stage | 5~60 seconds | 10~20 seconds | Observe pressure changes |

| exhaust stage | 1~5 seconds | 1~3 seconds | Release test pressure |

Intelligent time control

Intuitive setup interface: Touch screen operation, values are entered directly, what you see is what you get.

Program pre-storage function: Pre-set test scenarios for different products with complete time parameters. One-click recall to avoid repetitive settings.

Advanced Programming Mode: Supports complex test sequences such as multi-stage pressurization, intermittent testing, and other special needs.

III. Practical implications of time regulation

Balancing efficiency and precision

- too short: May miss slow leaks

- excessive: Impacts productivity and increases costs

- happen to be: Guaranteeing inspection accuracy and production speed at the same time.

The key to cost control

Airtightness testing compared to the traditional water immersion method, time fromTens of minutes reduced to tens of secondsThis ability to regulate time directly determines the efficiency of the production line.

IV. Advantages of time regulation in Precision Engineering

Second precision controlTime adjustment accuracy is up to 0.1 second, which meets various precision inspection requirements.

Multiple programs coexistThe test program can store 50+ test scenarios at the same time, covering the needs of different product lines.

New energy motor airtightness test cases, different products, a key to switch the test program

Real-time monitoring and feedback: Real-time display of remaining time and current status during testing, transparent and controllable operation.

Temperature compensation function: Automatically adjusts the accuracy and repeatability of the instrument according to the ambient temperature for the same detection time to ensure the stability of the results.

V. Recommendations for practical application

Initial setup strategy

- Reference standard requirements: Initial values are set based on the relevant IP standards.

- Small batch verification: Verify the reasonableness of the time setting through a small sample test

- Progressive optimization: Fine-tune the time of each stage according to the actual test results

Production stage optimization

- Standardized time: Determine the optimal parameters and then solidify them into a standardized scheme

- Exception handling: Setting the extended time option for anomaly detection

- data analysis: Regular analysis of test data for continuous optimization of time settings

Summarize

The time adjustment function of the airtightness tester is not an optional add-on, but a core element to ensure testing quality and productivity.

Precision Engineering'sAir tightness testing equipmentReducing traditional 'hourly' tests to 'seconds'This revolutionary time-control capability is the best expression of the manufacturing industry's pursuit of efficiency and precision.

Need to know more?

If you want to know more about the specific program of airtightness test time setting, or need to have sealing waterproof testing needs for specific products, welcome to contact us!Precision Engineering AirtightnessProfessional team.

We will provide you with an optimal time allocation solution based on your product characteristics and quality requirements.

Original Statement::This article by the Precision Industrial Technology technical team original, based on practical application experience and customer feedback collated, reproduced please specify the source.