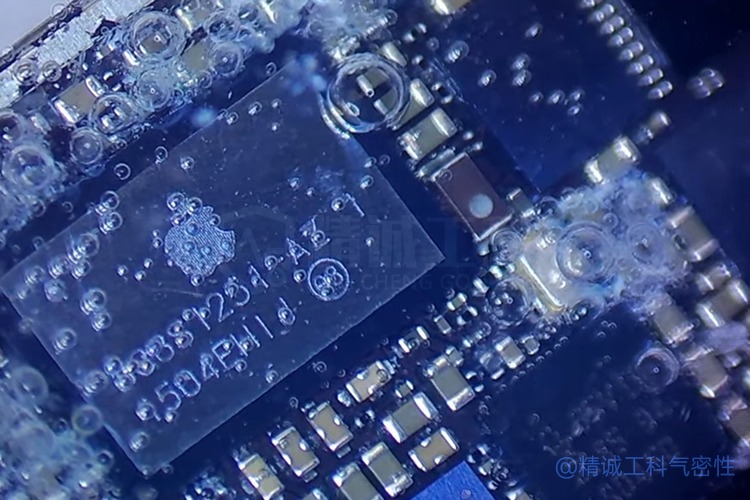

In the manufacturing industry, hermeticity testing is a critical part of ensuring product quality and safety. Let's take the cell phone manufacturing, if there is even a small gap in the shell of the phone, moisture and dust can get in from the outside, which can lead to short-circuiting, heating and other failures of the components. It can be seen that a small leakage hole can cause a big trouble. So.The control of product sealing is directly related to the quality and safety of use.

How to judge the sealing performance? The key is the "leakage value" indicator. According to the size of the leakage value, it can be categorized into "large leakage", "medium leakage" and "slight leakage", and each situation corresponds to different follow-up measures.

1. What is a sealing test

The so-called sealing test is to measure the amount or rate of leakage of gas or liquid leakage inside the product under specified pressure or vacuum conditions.This amount of leakage, which is what we call the leakage value, is used to judge whether the sealing performance of the product is up to standard.So, what exactly do major, medium, and minor leakages mean?Based on the size of the leakage value, a sealing test will categorize the degree of leakage into one of the following three categories:

① micro-leakage: the leakage value is within the specified qualified range, indicating that the product has good sealing performance and can pass the test.

② large leakage: the leakage value exceeds the maximum allowable value, indicating that there is a serious leakage of the product, which is a non-conforming product, need to be directly sentenced to scrap.

③ Medium leakage: The leakage value is between large leakage and micro leakage, which needs to be further analyzed to determine whether it is acceptable.

2. Why analyze small, medium and large leakages

Different levels of air leakage have very different effects on the product.Large leaks are likely to lead directly to serious failures or safety hazards, while micro leaks are often acceptable.

Knowing whether the leakage value is large or small helps to pinpoint the root cause of the problem, take targeted measures to deal with it, and improve the relevance of quality control.

If a major problem such as a large leak is not handled properly, it can result in significant economic loss and reputational damage. Poor sealing can also shorten product life and affect the customer's experience.

Therefore, through scientific analysis of large leakage, medium leakage and micro leakage, we are able to solve airtightness design problems according to local conditions, ensure product quality and improve customer satisfaction.

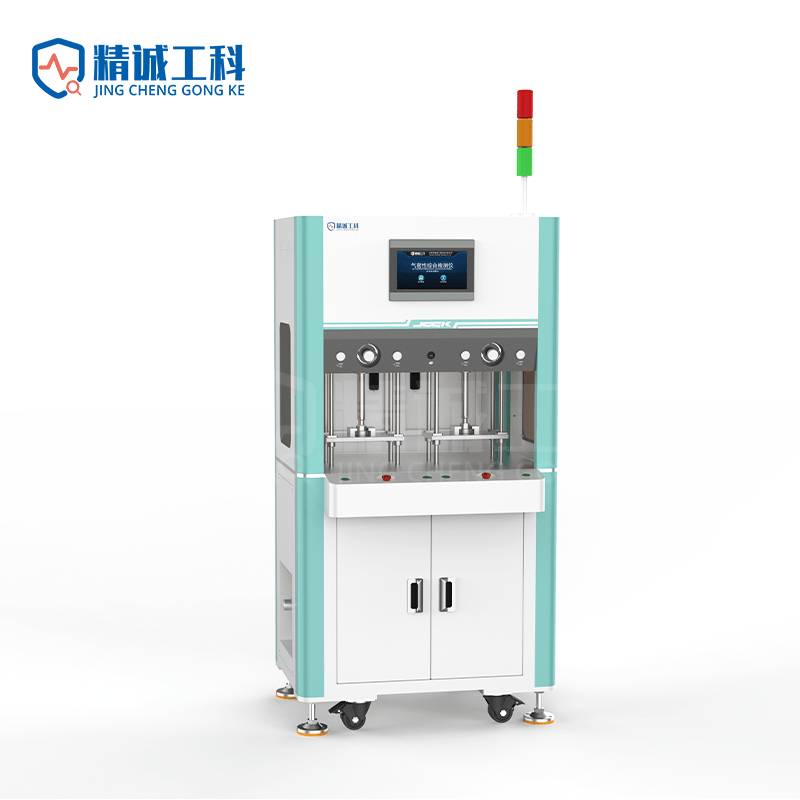

3. Application of sealing testers

Professional air tightness tester is widely used in all aspects of the product, mainly including:

- Product development phase:Test prototypes to validate design solutions and optimize structures.

- Manufacturing process:Inspection of intermediate products and critical components to detect and correct process defects in a timely manner.

- Pre-shipment quality control:All products must pass strict sealing inspection to ensure the quality is qualified before shipment.

- Regular quality control:From time to time, we conduct sampling tests on sold products to ensure the quality level.

Whether in a laboratory environment or at a production site, the hermetic tester plays a key quality control role.

4. How leakage is measured

So how exactly is the leakage value measured? Manufacturers need to use specialized airtightness testing instruments, which have the following main test methods:

- ① Positive pressure method:Inflate the workpiece under test, close the inflation valve after reaching the target value, and monitor the pressure change from inflation to pressure maintaining in multiple stages, so as to determine whether the product under test is leaking.

- ② Negative pressure method:Through the instrument will be tested product sealing cavity pumping to the target negative pressure value, monitoring the pumping process pumping and testing process in the various stages of the pressure change, to determine whether the product leakage.

- (iii) Volumetric quantification method:The workpiece under test is inflated, and the mass volume of gas filled into the product under test is monitored, and whether the product is leaking or not is determined by judging the mass and pressure changes in the mass volume.

- ④ Gas flow method:By real-time monitoring of the gas flow changes into the product under test, based on the flow changes to determine whether it meets the test standards.

- ⑤ Differential pressure method:Through the differential pressure sensor inside the instrument, the pressure difference between the tested part and the standard part is monitored in real time during the test pressure holding process, so as to determine whether there is leakage exceeding the standard.

When making measurements, the construction and material of the product, as well as factors such as ambient temperature and humidity, will all affect the final leakage value reading. In addition, the accuracy of the instrument itself and the method of use are also directly related to the accuracy of the test results.

5. Examples of practical applications of leakage values for gas-tightness testing

Leakage status of micro, medium and large leaks of the hermetic gauge

There are a wide variety of application cases for leakage values for airtightness testing in different industries and fields. For example, the above video example of hermeticity testing of a fully enclosed product demonstrates three types of leakage.

Micro Leakage (PASS)The test results, in a short period of time after the inflation, balance, detection of the three stages, monitoring the product there is a small leakage, the leakage value in the detection standard, at this time the instrument will determine the product airtight qualified.

Medium leakage (NG-S)The test results, that is, a short period of time to monitor the product's leakage value exceeds the test standard, at this time the instrument will determine that the product is not airtight.

Large leakage (NG-L)The results of the test, i.e. a short period of time to monitor the complete leakage of the gas filled into the product.

6. Selection of airtightness instruments

Selection of a suitable airtightness tester is critical to obtaining accurate leakage value data. The following aspects should be thoroughly considered:

- Measurement range:To cover the pressure or vacuum range required by the product under test.

- Detection accuracy:Accuracy within 1Pa is generally required for accurate and reliable readings.

- Response time:The faster the response, the more efficient the detection.

- Repeatability:Ensure consistency of results across multiple tests.

- Operator Interface:The user-friendly interface helps to increase productivity.

- Compatibility:To accommodate different sizes and types of products under test.

- Function:Select data logging, analysis, and printing functions as required.

- Durability:Long-term use requires good durability and maintainability.

- Brand Awareness:The more well-known brands of hermetic testing equipment are imported ATEQ Adeche and domestic JCGK Chencheng Industrial Technology, etc., which are used by large domestic manufacturing companies.

- Localized services:For domestic users, JCGK, as a local airtightness testing leader, has a quick local service response to ensure the long-term and efficient operation of the equipment.

Summarize

Through the introduction of the above content, I believe that we have a deeper understanding of the importance of leakage value measurement and the analysis and determination of large and medium-small leakage of the gas tightness meter.

As the 'lifeline' of product quality and safety, hermeticity testing plays an indispensable and important role. Choosing the right airtightness test instrument and method is crucial to fundamentally control product quality and improve production efficiency.

Whether it is the imported brand ATEQ, or the domestic brand JCGK, with advanced technology and perfect service, for the manufacturing industry to escort the quality of products.Let's pay attention to airtightness testing together, improve quality and safety awareness, and deliver assured quality products to consumers!