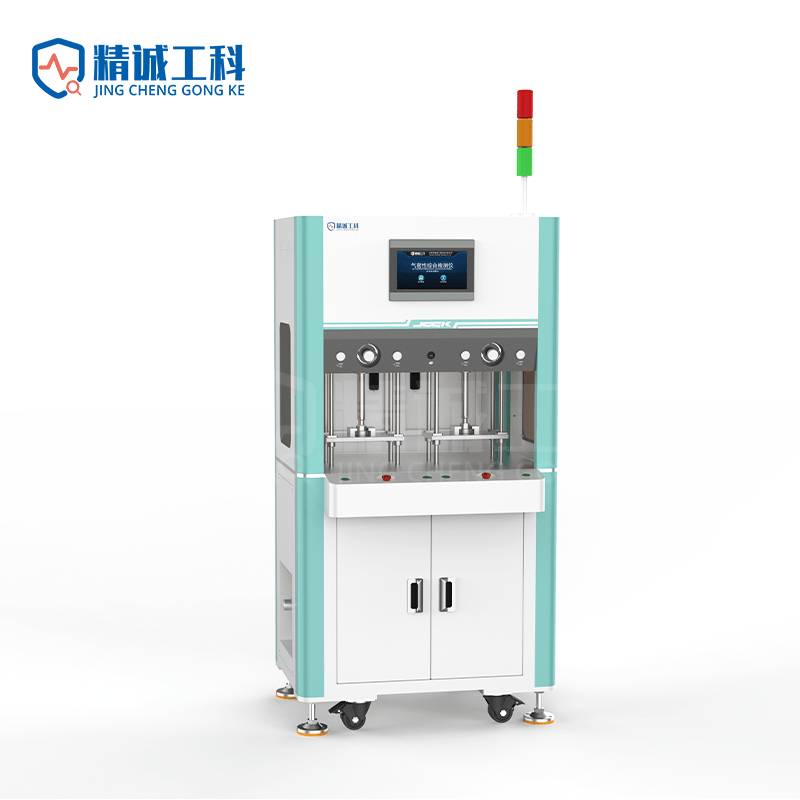

In the world of manufacturing.Air tightness testerIt is like an attentive quality inspector who silently guards the quality of the product. Choose the rightAirtightness TesterAnd setting the parameters correctly is essential to improve productivity and product quality.

Today, let's uncover theAir tightness testerWe will also discuss how to skillfully operate this "quality guardian" and learn about the key parameters when purchasing.

I. ShoppingAir tightness testerKey parameters of the

Choosing the right airtightness tester is like equipping a production line with a capable assistant, and requires consideration of the following key factors:

- Measurement accuracy:Typically between 0.1Pa and 1Pa, the higher the accuracy, the better the ability to detect small leaks, just as a microscope can see details imperceptible to the naked eye.

- Repeatability:The error should be controlled within ±1%rdg to ensure stable and reliable test results, just like an experienced quality inspector.

- Test range:Depending on the product selection, it generally ranges from a few milliliters/minute to several hundred liters/minute and is as adaptable as an all-round athlete.

- Response time:qualityAirtight test equipmentTypically responds within 10 milliseconds, faster than a human blink of an eye, increasing test efficiency.

- Temperature compensation function:Eliminating the effect of ambient temperature on test results is like putting a 'thermostatic suit' on the device.

- HMI:The intuitive and easy-to-use interface reduces operational errors and is as easy as communicating with an old friend.

- Data management capabilities:Consider data storage, analysis and export functions for easy quality traceability, comparable to a dedicated record keeper.

II. Parameter Setting Operation Procedure

grasp (often fig.)Airtightness Testeroperation, like learning to drive a high-performance automobile, requires familiarity with the following steps (in the form of Jingcheng Industrial Technology)Airtightness Tester(for example):

1. Select the test instrument:Select the appropriate test method according to the product characteristics, such as pressure decay method or differential pressure comparison method.

2. User rights creation:Log in to the airtightness testing system according to user roles, with different users corresponding to different permissions.

3. User login settings:Follow the User Wizard prompts to enter "System Settings" to open the door to testing.

4. Enter the parameter settings:Select "Parameter Setting" in the main interface to confirm the parameter setting.

5. Set the test pressure:Typically not exceeding 80% of the product's maximum withstand voltage value ensures safety and effectiveness.

6. Set the test time:This includes inflation time, equilibrium time (also called stabilization time) and detection time, just like the fire control in cooking.

7. Setting standards for leakage:The maximum permissible leakage is set according to the product quality requirements and the passing line is drawn.

8. Enable temperature compensation:If the ambient temperature fluctuation is large, it is recommended to turn on this function (Precision Engineering instrument comes with temperature compensation function, you can ignore this step), so that the test results are more accurate. (I had an interesting case once. One factory's test results were always very different between summer and winter, and it turned out that the temperature effect was not taken into account. So, good equipment should be able to automatically adjust for the effects of temperature.)

9. Save the test program:Be sure to save the parameter configuration when you're done to avoid wasting your hard work on tuning.

10. Pressure synchronization setting:Synchronize the instrument air pressure with the product test pressure to ensure accurate test results.

11. machine learning setup:According to set the instrument comes with the analysis of the characteristics of the standard sample parameters, if necessary, adjust the parameters to ensure that everything is safe.

After completing the above parameter settings, start the airtightness fixture, you can test the airtightness of the product, after the completion of the test, you can view the production efficiency statistics in the "data query" interface to retrieve the relevant test data.

III. Customer Case Sharing

Automotive parts manufacturer:

Adoption of Jingcheng EngineeringAirtightness TesterAfter that, the product qualification rate increased from 79.5% to 99.9%, becoming the industry quality benchmark.

Automotive SensorsAirtightness Tester

Manufacturer of household appliances:

A well-known water purifier manufacturer introduces Jingcheng Industrial Science and Technology Co.Comprehensive air tightness testerThe test time is shortened by 40% and the accuracy is improved, dramatically increasing production efficiency and product quality.

Comprehensive water purifier cartridge tester

Medical device manufacturers:

A Ventilator Manufacturer Uses Precision Industrial TechnologyWaterproof Test EquipmentAfter that, the product reliability was significantly improved and the customer complaint rate dropped 80%, which made an important contribution to saving lives during the epidemic.(This case signed a confidentiality agreement and is not suitable for display)

Summarize

In the era of Industry 4.0, quality is the lifeblood of a company. Choosing a reliableAir tightness testing equipmentProducts such as Precision Engineering's are an investment in the future of the business.

Selecting the rightAir tightness testerand operated correctly, is vital to improving product quality and productivity.Precision EngineeringAirtightness TesterWith its excellent performance, it plays an important role in many industries such as automotive, home appliances, medical and so on, helping enterprises to improve product quality, reduce costs and enhance market competitiveness.

Let's work together to create excellent products with science and technology and quality, and stand invincible in the fierce market competition!