Waterproof rating test is a test method to check whether a product is waterproof or not. The reason why products need to be tested for water resistance is that water resistance has a great impact on the quality and function of the product. The specific reasons are as follows:

Protects the internal components of the product:If the product is not sufficiently waterproof, moisture may penetrate into the interior of the product and cause damage to internal components such as circuit boards and electronic components, thus affecting the performance and life of the product.

Increase product life:Passing the waterproof test ensures the service life of the product underwater or in a humid environment. If the product is unable to withstand moisture, the service life will be limited.

Meet market demand:Water resistance is an important requirement for products that need to be used in wet or underwater environments, such as swim watches, bathroom stereos, and waterproof cell phones.

Protecting the safety of users:If the product is not waterproof when in use, the user may be exposed to electric shock or other hazards.

Therefore, waterproof testing is essential for products that need to be used in wet or underwater environments.

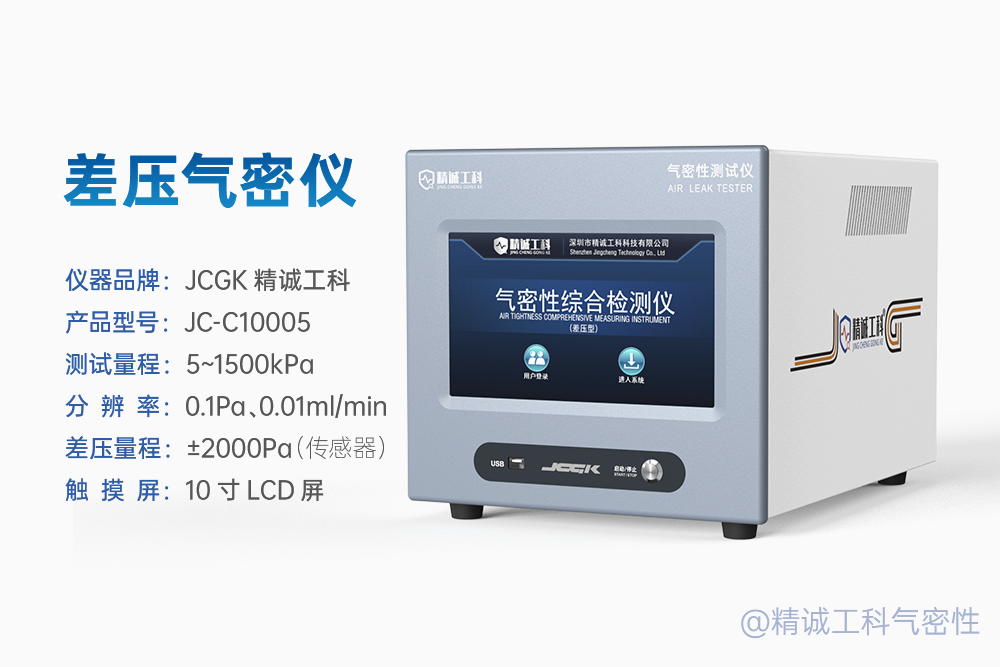

Water, gas and helium tests are all common methods of waterproofing.These three methods are represented by the following instrumentationWaterproof Test Chamber,Airtightness Tester,Helium Leak DetectorThe principles and methods are as follows:

Ⅰ.water quality control

Waterproof Test ChamberLeaks are detected by immersing the product being tested, utilizing the density and surface tension of water. The product being tested is usually a container, pipe, seal, etc. The inspected product is placed in water and bubbles appear if a leak exists. This method is suitable for testing large equipment and components.

Pros:Simple and easy to use, low cost.

Drawbacks:Can only detect the large hole vulnerability, can not detect the small hole vulnerability, is not applicable to the detection of high-pressure containers, the product test is also required after the completion of the drying and so on, the steps are cumbersome and time-consuming and labor-intensive, the method is applicable to the detection of large-scale equipment and components, there are limitations.

Ⅱ.aeronautical

airtightness leak detectorUtilizing compressed gas, it is injected into the interior of the inspected product and then observed with theAir tightness testing equipmentThe pressure curve changes to observe the air leakage.

Pros:Simple to operate, can detect small holes, cracks and other small holes, widely used, fast detection speed, and can even do a few seconds to measure a product.

Drawbacks:Can not detect the tiny leaks, can not accurately find the leakage point of the inspected product, the use of large pressure needs to be equipped with a booster pump.

Sealability testing of automotive components usingDifferential Pressure Airtightness Tester

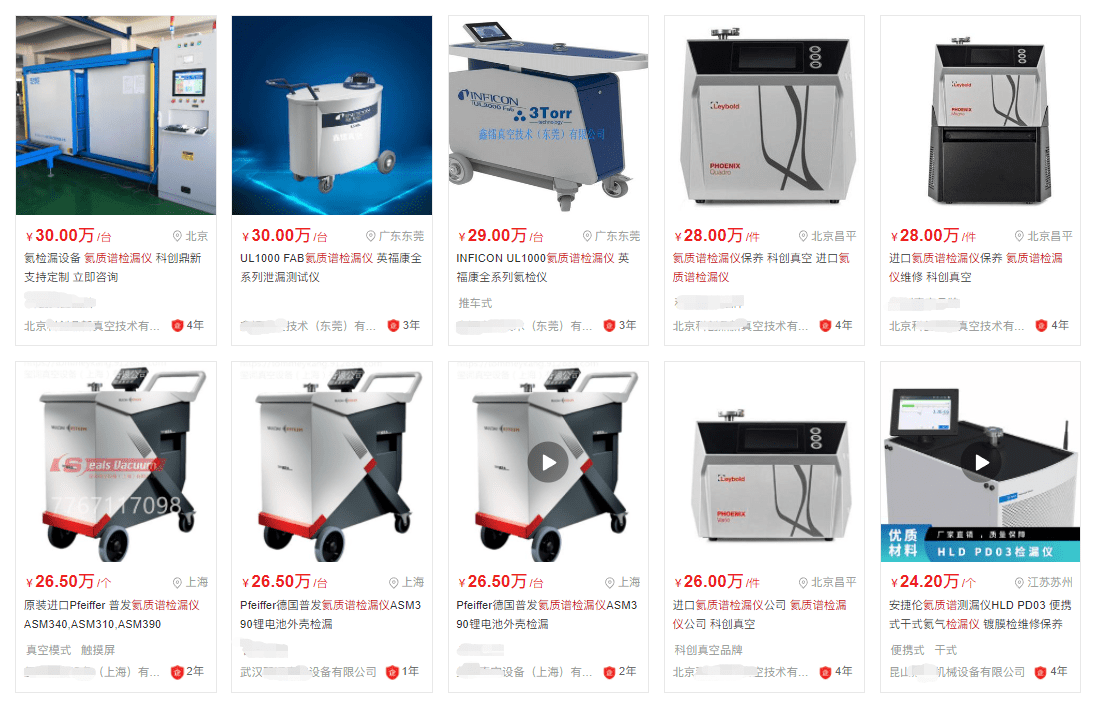

III.helium detection

Helium Leak DetectorUsing the properties of helium (helium is an inert gas), it is injected into the product under test and the leak is observed using a helium gas analyzer.

Pros:It can detect tiny holes with high accuracy and can be used to inspect high-pressure, large-volume, closed container products.

Drawbacks:Requires specializedhelium detectorThe cost is higher.

IV. Summary

Water, gas and helium tests all have their own advantages and disadvantages, and the selection of a suitable leak detection method needs to be considered in the light of the nature of the product being tested, the environment in which it is to be used, and other factors.

- If the product output is small and the waterproof requirement is not so strict, you can consider water inspection;

- If there is a high demand for product capacity and a clear requirement for a waterproof rating, you can consider gas checking;

- If there is a high demand for product capacity, a clear requirement for a waterproof rating, and a need to find leaks in the product, then helium testing may be considered.

At present, the Shenzhen Jingcheng IndustrialAir tightness testing equipmentAccuracy up to 0.1Pa(i.e., test accuracy of 0.075%F.S.), comparable with theHelium Leak DetectorThe accuracy of the test is due to the manufacturer's continuous investment in technological research and development to achieve the results.

At the same time, with the development and maturity of the manufacturing industry and waterproof testing has become a necessary part of the factory testing of new products, making the waterproof rating has become a standard of measurement for many users when purchasing products.

There is no doubt that gas detection, due to itsSuperb price/performance ratioThe related gas detection equipment such asAirtightness TesterIt has slowly become the mainstream of the marketThe

To learn more detailed industry testing programs and application cases, please pay attention to [Precision Engineering Airtightness]