What are the main models of JCGK Leak Tester? Airtightness tester chapter, with selection guide

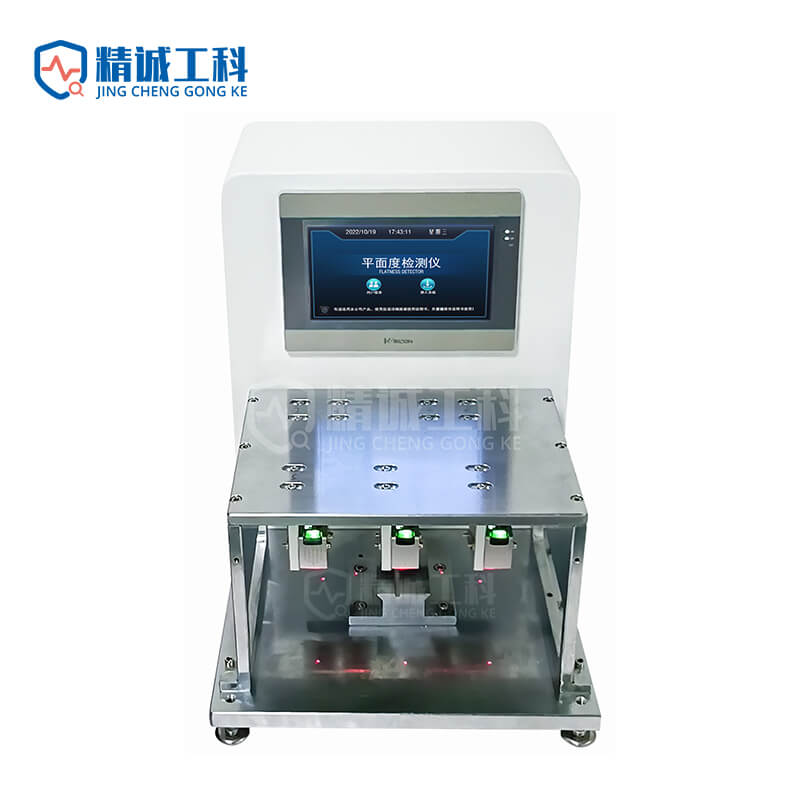

As a leading brand in the airtightness testing industry, JCGK has launched a variety of airtightness testers to meet the testing needs of different industries and different application scenarios. From basic single-channel airtightness testing to high-end multi-channel automated testing equipment, JCGK's product line covers a wide range of testing needs.